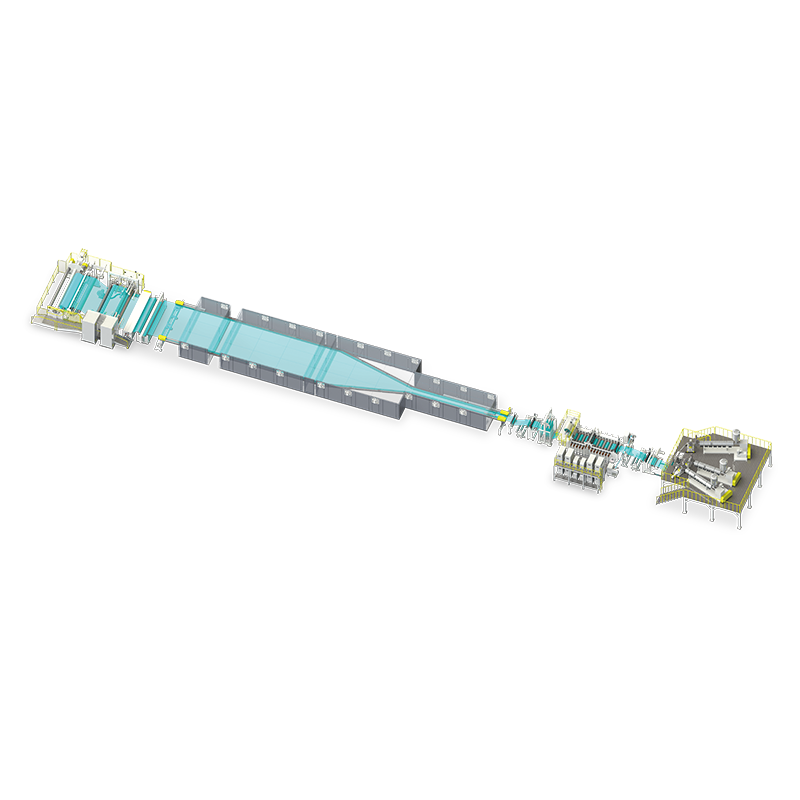

PET Bisynchronous Stretching Line

Features

PET film has excellent mechanical properties, and its strength and toughness are the best among all thermoplastics. Its tensile strength and impact strength are much higher than ordinary films; it has good stiffness and good stability and is suitable for printing, paper bags, etc.

PET shrink film is known for its excellent transparency and barrier properties. After bisynchronous stretching, film transparency is especially high. PET shrink film is used for generic packaging, labeling, special packaging (such as for DVDs), baked goods, keeping fresh fruits and vegetables, and synthetic paper labels.

Specifications

| Item | Description |

|---|---|

| Materials | BOPVC/BOPP/PLA/PET/PE/PA |

| Extruder | Main screw φ90mm, φ100mm, φ120mm, φ150mm, φ180mm Auxiliary screw φ35mm, φ55mm, φ75mm |

| Productivity (max) | 600kg/hr |

| Line Speed (max) | 200m/min |

| Automatic Die Head | Product width 2500mm~6000mm Product thickness 0.03mm~0.06mm |

| Electronic Controlled Edger | 1 Set - Static pressure adsorption forming |

| Cast Forming Rollers | φ300~φ500mm x 2~3set |

| Longitudinal Stretching Unit | 2 Sets |

| Horizontal Stretching Unit | 1 Set - 26m~40m |

| Auto Thickness Tester | 2 set |

| Corona Treater | 2 set |

| Swing | 1 Set - Automatic edger |

| Haul off Equipment | 4 Sets |

| Rolling Station | 2 Sets - Dual spindle center roll |

Application

labeling, special packaging (such as for DVDs), baked goods, keeping fresh fruits and vegetables, and synthetic paper labels.