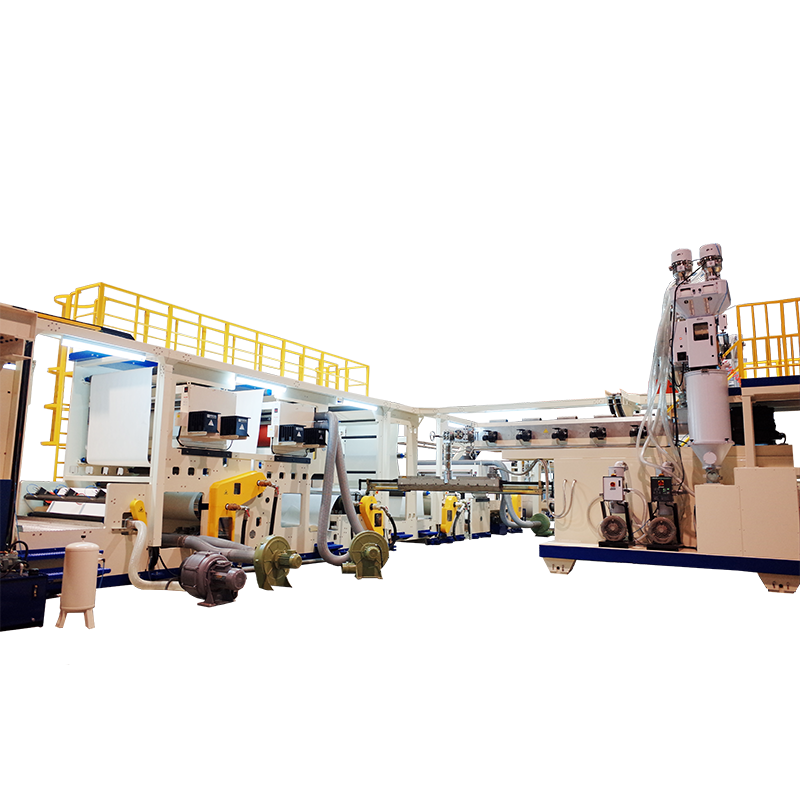

Tandem Extrusion Lamination Machine: PE/PP/PLA, Double-Side

Features

This double-sided film extrusion equipment has mechanical high precision, high productivity, and high efficiency and economy. The winding station includes a surface rewinding and a fully automatic shaft switching system. The laminating machine offers a wide range of applications and processes, including single extrusion, double extrusion, and coextrusion lines. The machine offers many paper or film coatings, high quality, and stable lamination, which can be tailored to your needs.

The film extrusion equipment is extruded and cast, and adhered to the surface of a flexible substrate such as paper or film after stretching, and is cooled and shaped to form a composite material having both plastic toughness and functional properties of the substrate. Widely used in woven fabrics, paper tableware, food packaging bags, etc.

Specifications

| Item | Description |

|---|---|

| Un-winder | Fully-automatic film release device |

| Control | Touch panel, automatic control system |

| Feeding | Volumetric dosing system |

| Extruder | Ø75、Ø100、Ø120 |

| Material | PE / PP / PLA |

| Line Speed | 100-300m/min |

| Coating Thickness | 8 - 40μ |

| Sheet Width | 800mm-4300mm |

| Output | 100-450kg/hr |

| Laminating Substrate | Paper / Aluminum foil / PET / BOPP |

| Laminating Substrate Thickness | 12 - 200μ |

Application

paper tableware, food packaging bags, etc.