Features

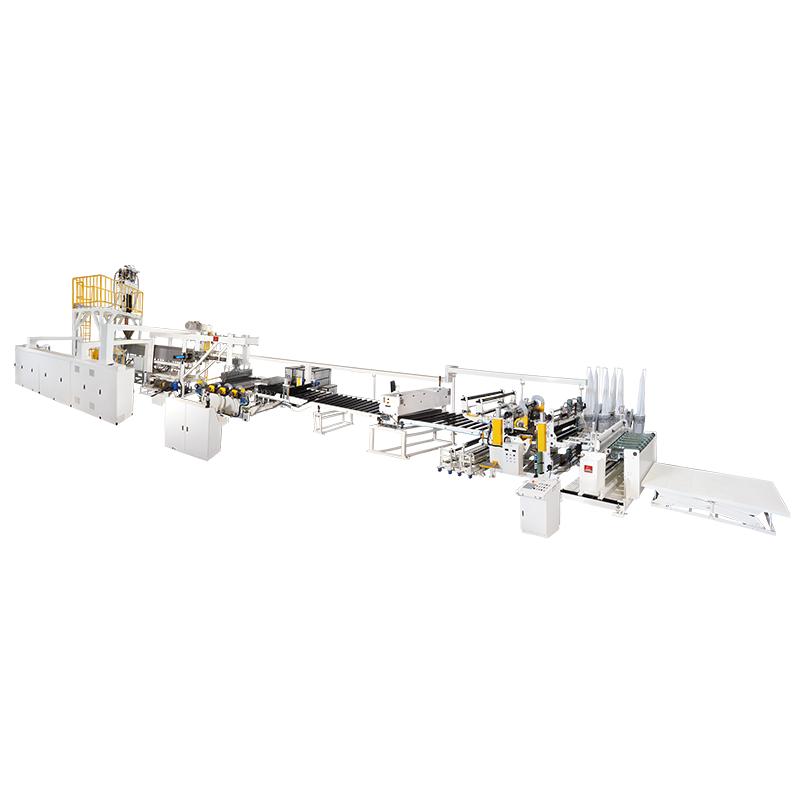

The T-die head and the forming calender maintain a stable and flat plate. The extruded plate is firm and good in quality, has very good temperature resistance, and is suitable for high-temperature thermoplastic processing and molding. We can customize the machine to achieve customers' requirements.

PC&ABS Sheet Co-Extrusion line is designed for producing suitcases, The process of making leather suitcases is generally known to have two methods:

injection and extrusion. For how to use recycled materials, we adopt the co-extrusion method. Using 80% ABS recycled materials as the bottom layer, it still retains the high impact resistance and hardness, toughness, and rigidity. 20% of the outer layer is made of PC new material, depending on the brightness and beauty of PC, then through the process of thermoforming to make a beautiful suitcase.

The feature of co-extruder

Dehumidifying and Drying feeding system -

In order to achieve better product quality, the raw materials must be properly dehumidified and dried to take away the moisture in the raw materials.

Extruder -

Designed the most suitable screw to produce the product which according to the characteristics and conditions of different raw materials. It could make the melting and mixing of raw materials to achieve the best results.

Screen changing system -

Non-stop screen changing system to reduce the waste of raw materials.

Gear Pump -

Precisely control the amount of raw material discharged, and it can be linked with the host motor to maintain a fixed amount of material.

Feedblock -

Control the stable combination of PC and ABS, uniformly control the layering ratio and thickness.

T-Die -

Extruding the raw materials uniformly and stably, the flow channel in the die is analyzed by die flow, and the flow rate at each point on the left, center and right of the die can be controlled to be evenly extruded.

Calendar -

Horizontal three-wheel design, the middle wheel can be used to produce and change different patterns. The gap between the wheels can precisely control the embossing and thickness of the plate sheet.

Unwinding Rack -

In response to the needs of various styles and color changes in the production of suitcases, the unwinding rack can print the desired pattern or color on the ABS or PC film in advance, and it can be pasted on the board during the production process through this mechanism.

Specifications

| Item | Description |

|---|---|

| Materials | PP |

| Extruder | Twin screw extruders are available in φ58/58mm~φ92/92mm according to customer preference. Single screw available in φ90mm~φ180mm |

| Productivity | 200kg/hr ~ 800kg/hr |

| Extruder HP | 190~375kW High efficiency AC three phase frequency converter motor |

| Line Speed (max) | 12m/min |

| T-DIE | Die head width 1000~2100mm Product thickness 0.6~4.0mm |

| Forming Rollers | φ300~φ500mm x 3 Sets |

| Haul-off Equipment | 1set |

| Annealing Oven | 2~3 Sets |

| Corrugating Machine | Depends on pattern |

| Edge Trimmer | 2 Sets |

| Waste Crusher | 2 Sets |

| Cooling Equipment | 1set |

| Micro-computer Cutting Unit | 1set |

| Automatic Hydraulic Lifter | 1set |

Application

ABS Sheet application: ABS is a rigid, shock-resistant material suitable for a wide variety of applications, including auto parts and containers. Its flowability and high anti-variant coefficient make it ideal for thermoforming.

PC Sheet application: PC sheets have heat-resistance, UV-resistance, and light transmission properties, making them ideal light building materials. PC’s high impact resistance also makes it ideal for use in other applications, including suitcases.

PP Sheet application: PP is the most widely used material in the plastic packaging market. A strong, durable material with high resistance to impact and bending, PP is commonly used in containers and packaging.