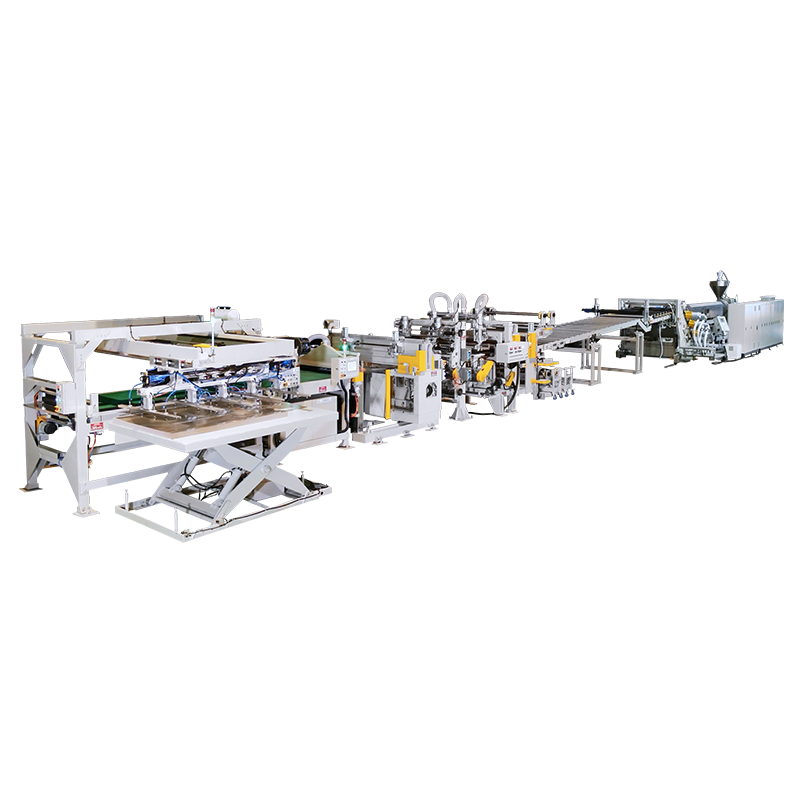

Sheet Extrusion Line for Optical Panel Production

Features

This model can produce optical PMMA sheet and impact resistance PC sheet.

The optical PMMA sheet has excellent light transmittance, and high transparency, and it is not easy to change color after long-term use. It is widely used in various electronic instrument panels, touch panels, mobile phone screens, flat-screen TVs, light guide plates, diffusers boards, and so on. It also has characteristic of easy forming, it used in various of groceries and as decoration sheet. For example, reflective sheet for transportation, light cap for traffic light and furniture.

PC sheet has excellent anti-impact, used in widely temperature range, high transparency and good anti-flaming. It also could coat UV layer to extend using time and reduce yellowing. It is used to apply in display window, skylight, lightbox and so on.

Diffusion Plate VS Optical Guide Plate

- The diffusion plate’s durability and stability improve the product’s transparency and light diffusion properties.

- The optical guide plate’s high transparency and high light transmittance improve the brightness and uniformity of the finished panel.

Specifications

| Item | Description |

|---|---|

| Extruder | Main screw φ100mm, φ120mm, φ150mm, φ180mm Auxiliary screw φ35mm, φ55mm, φ75mm, φ100mm |

| Extruder Power | 10kW~450kW High efficiency AC three phase frequency converter motor |

| Output | 800kg/hr |

| Line Speed (max) | 4M/min |

| T-DIE | Die head width 960mm~2550mm Product thickness 4~25mm |

| Forming Roller Unit | DCalender Rollers x 3 pcs |

| First Haul Off Roller Unit | Haul Off Roller x 4 pcs |

| Auxiliary Oven | 2 set |

| Film Laminating Unit | 1 Set - Single or both surfaces |

| Cooling Platform | 2 set |

| Edge Trimming Unit | 2~4 Sets – Includes dust collection equipment |

| Second Haul Off Roller Unit | Haul Off Roller x 4 pcs |

| Cross Cutting Unit | 1 set |

| Stacker | 1 Set , 6000~12000 mm (Option) |

Application

Screens for flat-screen televisions, computers, PDA, and mobile phones.