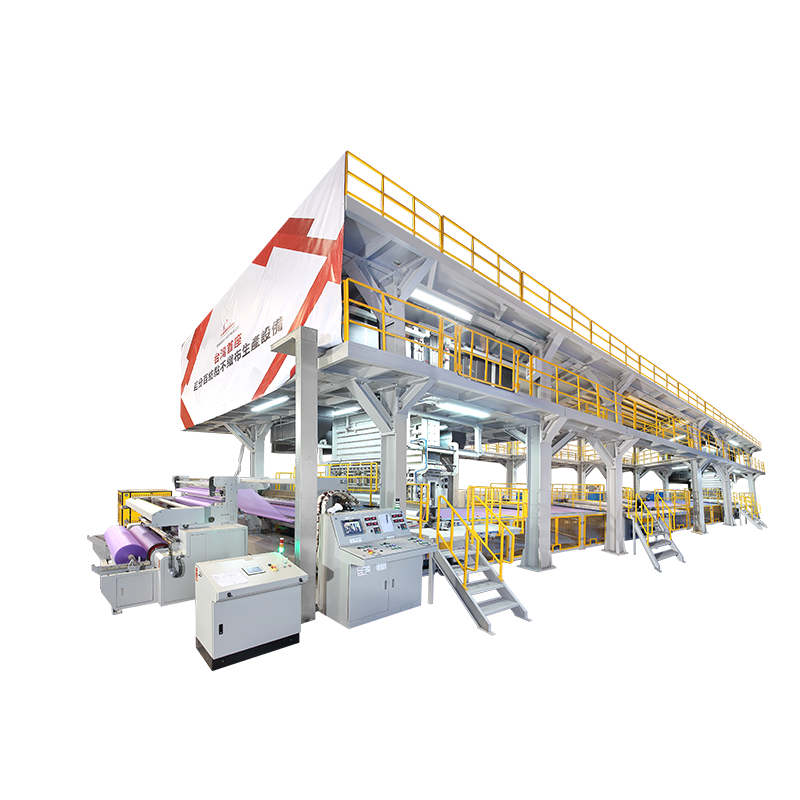

Spunbonded Nonwoven Fabric Machinery

Features

Also known as non-woven fabric, it is a kind of non-woven fabric. Through the spun-bond method of polymer web-forming technology, the raw materials are melted and extruded from the nozzle through the extrusion equipment, and the superfine fibers are formed through the quenching of the web to form a net Shape structure. This process is short, high in output, low in cost, and fast in change, and has a wide range of raw materials to meet various applications in the end market.

Advantage:

- Lightweight: Polypropylene resin is the main raw material for production, with a specific gravity of only 0.9, which is only three-fifths of cotton. It is fluffy and feels good.

- Softness and comfort: It is composed of fine fibers (2-3D) and is formed by lightly hot-melt bonding. The finished product is moderately soft and comfortable.

- Good water repellency and air permeability: The finished polypropylene product has good water repellency. It is composed of 100% fiber and has a porosity and good air permeability. It is easy to keep the cloth dry and easy to wash.

- Good physical properties: It is made of polypropylene spun yarn directly laid into a web and thermally bonded. The product strength is better than ordinary staple fiber products, the strength is non-directional, and the vertical and horizontal strengths are similar.

- Environmental protection material

Specifications

| Item | Description |

|---|---|

| Control system | HMI control automatically |

| Feeding system | Auto-sucking machine |

| Material | High MI Polypropylene (35~45) |

| Main Extruder | Ø75mm or Ø100mm or Ø120mm |

| Mechanical Line Speed (Depends on No. of the extruder) | Max. 60~300m / min |

| Available width | 600mm-1600mm |

| Output/day | 1000kg/day-10000kg/day |

Application

Hygiene products: Baby diapers, Adult incontinence products, Sanitary napkins, Patient pad

Medical market: Medical hats, isolation gowns, shoe covers, bed sheets

Industrial market: tea bags, suitcase linings, suit covers, shopping bags