Features

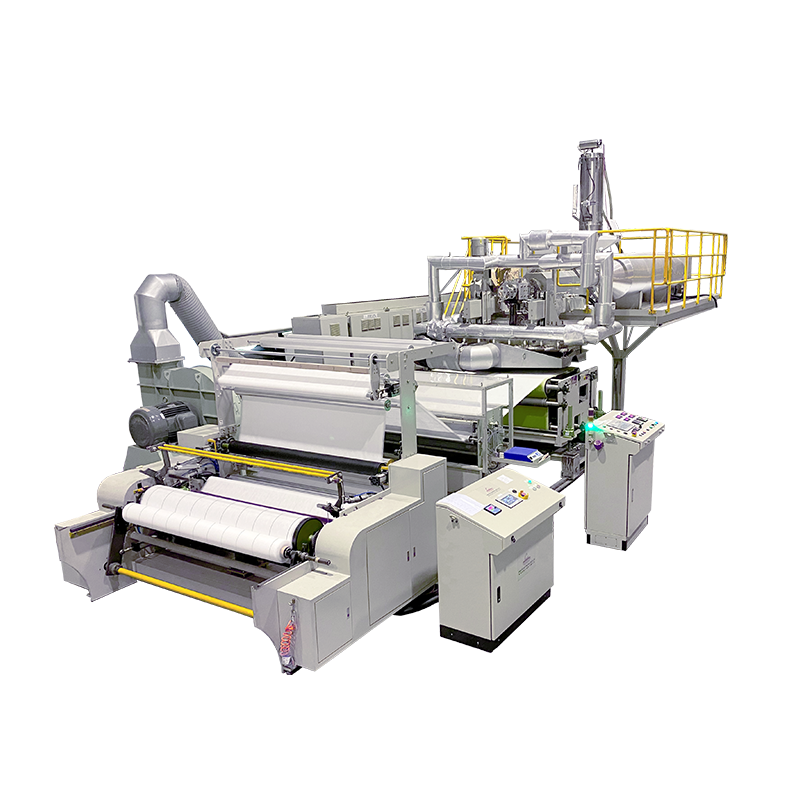

The melted molecules are squeezed into the high-speed hot airflow through the extruder, and then the polymer melt is spun out through the spinneret of the ultra-fine nozzle to form ultra-fine fibers, which are blown vertically onto the collector screen and accumulated into ultra-fine fibers. Fiber network structure.

Depending on the fiber diameter produced, a high output rate can be performed.

The ultra-fine fibers of the meltblown nonwoven fabrics can absorb static electricity in the meltblown nonwoven fabrics through the electrostatic electret technology so that it can absorb viruses and bacteria that have penetrated the surface. It is very suitable for composites that require filtration, shielding, heat insulation, and oil absorption. E.g. materials separately for masks, air/ liquid filter, thermal insulation, isolation, sound insulation, environmentally friendly oil-absorbing and wipe papers.

Specifications

| Item | Description |

|---|---|

| Control system | HMI control automatically. |

| Feeding system | Auto-suction machine |

| Material | High MI Polypropylene (1300~1800) |

| Main Extruder | Ø75mm or Ø100mm |

| Mechanical Line Speed | 40M/min |

| Available width | 600mm-1600mm |

| Output/day | 500kg/day-2000kg/day |

Application

Medical products: Mask, Protective clothing

Thermal insulation application: ski wear

Filter products: Coolant filter, Air filter, HEPA filter, Air-conditioning filter